radiator

-

Hot

Magnesium alloy die castings

Magnesium alloy extrusion process : heating ingot → primary extrusion → cutting intermediate billet → heating → secondary extrusion → artificial aging → stretching and straightening → cutting head and tail and taking sample → roll Straightening → manual straightening → inspection → cutting and printing → oxidation coloring → finished product inspection → packaging → storage. Process characteristics: Magnesium alloys are only allowed to be heated in air resistance furnaces; in order to prevent burning, the highest heating temperature of various alloys is 470℃; the highest extrusion speed is 20m/min, which is faster than hard aluminum alloy, but only soft About 1/3 of the alloy; the shrinkage rate of the magnesium alloy extruded material is larger than that of the aluminum alloy, so the die size should be enlarged accordingly; the material should be heated to 150℃~250℃ during the tension correction, while the aluminum alloy material is at room temperature Straighten.

Email Details -

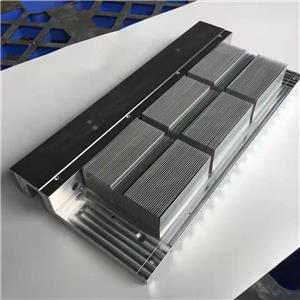

Skived fin heat sink

Skived fin heat sink Friction stir welded heat sink Heat pipe thermal module Water cooler Stitched fin heat sink Extruded heat sink Stacked fin heat sink Cold forged heat sink The material of the copper fin is T2/CU1100

Email Details -

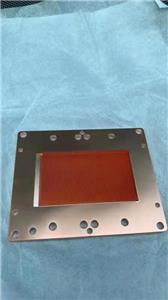

Copper heat sink

Skived fin heat sink Friction stir welded heat sink Heat pipe thermal module Water cooler Stitched fin heat sink Extruded heat sink Stacked fin heat sink Cold forged heat sink

Email Details -

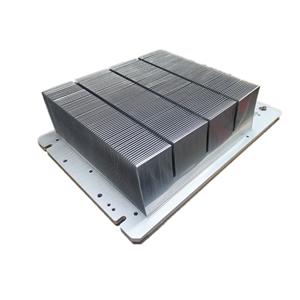

Heat sink part

Skived fin heat sink Friction stir welded heat sink Heat pipe thermal module Water cooler Stitched fin heat sink Extruded heat sink Stacked fin heat sink Cold forged heat sink The material of the copper fin is T2/CU1100

Email Details