support arm die castings

-

Hot

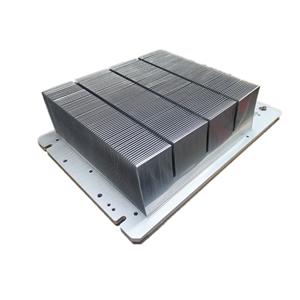

Magnesium alloy die castings

Magnesium alloy extrusion process : heating ingot → primary extrusion → cutting intermediate billet → heating → secondary extrusion → artificial aging → stretching and straightening → cutting head and tail and taking sample → roll Straightening → manual straightening → inspection → cutting and printing → oxidation coloring → finished product inspection → packaging → storage. Process characteristics: Magnesium alloys are only allowed to be heated in air resistance furnaces; in order to prevent burning, the highest heating temperature of various alloys is 470℃; the highest extrusion speed is 20m/min, which is faster than hard aluminum alloy, but only soft About 1/3 of the alloy; the shrinkage rate of the magnesium alloy extruded material is larger than that of the aluminum alloy, so the die size should be enlarged accordingly; the material should be heated to 150℃~250℃ during the tension correction, while the aluminum alloy material is at room temperature Straighten.

Email Details